- Company

- Products

Petrochemicals

Refining

Sustainability

- Napcon AI

- Our Platform

- Hybrid Process Modelling

- Resources

LC-Fining Reactor

Conversion Optimization

Maximize Yields. Extend Catalyst Life. Elevate Refinery Performance.

Physics Meets AI: Hybrid Models for Optimization.

Watch Demo

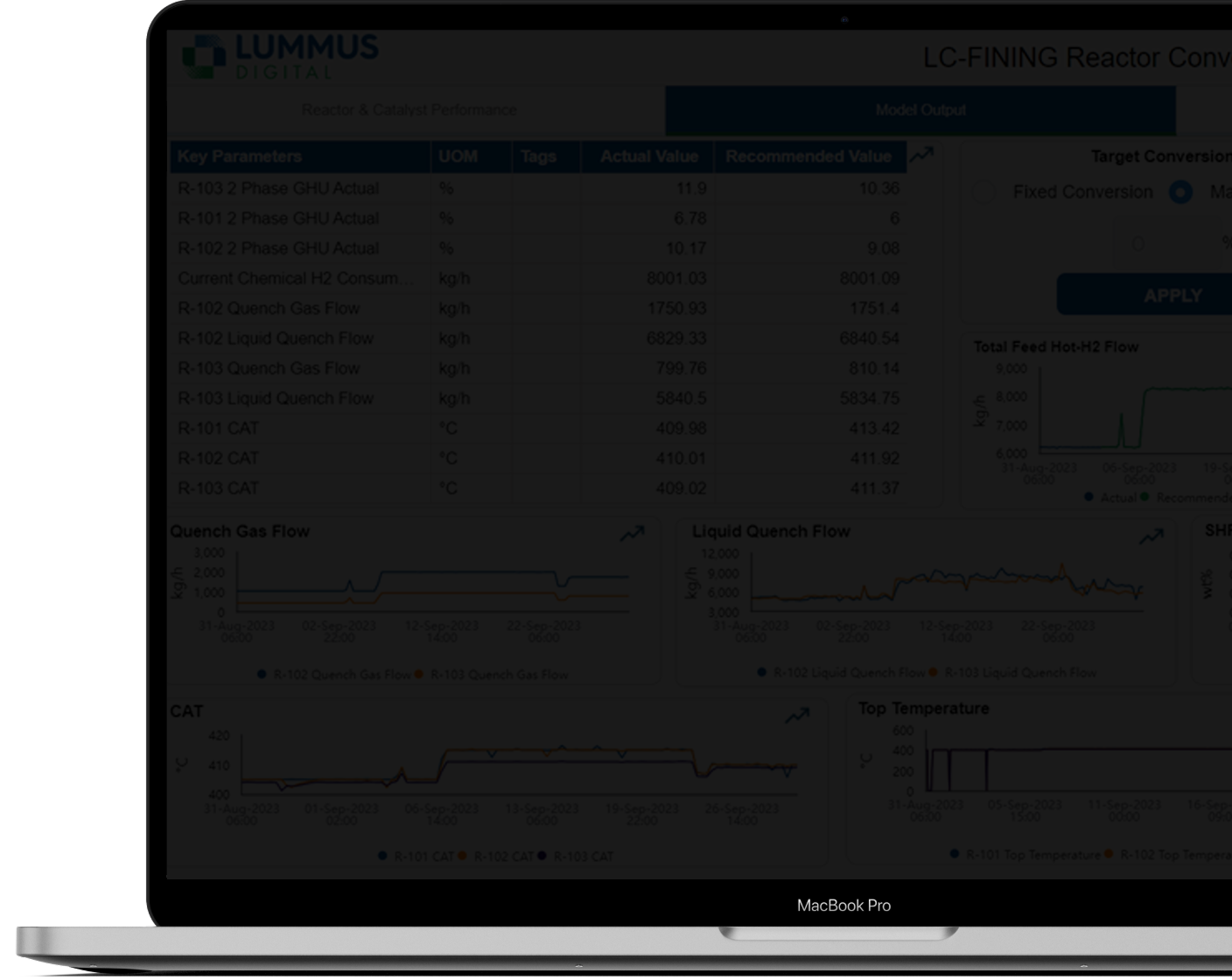

LC-FINING Reactor Performance Optimizer

1%

Increase in Reactor Conversion

50%

faster response to potential anomalies

Hybrid Model

Our model optimizes conversion by accurately predicting the maximum achievable yield, leveraging the Feed Operability Index and the predicted SHFT value in Vacuum Residue. This target conversion is then fed into the optimizer to generate precise DCS operator setpoints—such as Heater COT, Reactor CAT, and Feed H₂ flow—guiding operators to achieve optimal conversion efficiently and reliably.

Transform your Challenges into Opportunities

The LC-Fining Reactor Conversion Optimization Model aims to achieve maximum conversion by utilizing DCS and Feed Quality data in real time. The AI/ML platform delivers essential DCS setpoints and recommendations for plant operators and process engineers, facilitating the achievement of desired conversion rates.

Experience increased conversion, real-time predictions of downstream SHFT values, and optimized hydrogen consumption, transforming your operations for enhanced efficiency and profitability.

Pain Point

Unclear Potential Conversion

Benefit

Dynamic Target Conversion: Instantly adjusts to feed quality changes for accurate conversion targets.

Pain Point

Reactor Performance Limited by Vacuum Tower Fouling

Benefit

Optimized Reactor Efficiency: Utilize our Conversion and SHFT model to boost conversion while minimizing vacuum tower fouling.

Pain Point

Insufficient Vacuum Residue SHFT Values

Benefit

Hourly Insights on Vacuum Residue: Leverage our SHFT model for real-time predictions of vacuum residue values.

Pain Point

High Hydrogen Consumption

Benefit

Reduced Excess H2: Lower H₂ consumption during operations.

Pain Point

Reduced Conversion Efficiency Lowers Valuable Product Yields

Benefit

Optimizing temperature and hydrogen flow boosts reactor performance, increasing diesel and naphtha yields while enhancing efficiency and minimizing waste.

Pain Point

Increased Residues Strain Resources

Benefit

Advanced analytics and thermodynamic insights reduce residue, lowering energy and hydrogen consumption while minimizing equipment wear and extending its lifespan.

Pain Point

Catalyst Deactivation Leads to Higher Maintenance Costs and Reduced Refinery Flexibility

Benefit

Extended Catalyst Life: Minimize residue formation and thermal stress using predictive analytics, which reduces wear, maintenance costs, and operational downtime.

Performance Deviation Prediction

Key Parameter Monitoring

The Operator can select the mode of Optimization as

- Fixed Conversion

- Maximum Conversion

Process and Efficiency Trends

Using the FOI and predicted SHFT Value, the model calculates the Potential Conversion that can be achieved for the given Feed Quality.

Operational Benchmarking

The model generates and publishes recommended operator-controlled setpoints required to achieve maximum possible conversion.

Actionable Insights for Improvement

The dashboard displays a comparison plot of “Current Operation” vs. “Recommended Operation”, enabling clear visibility into performance gaps and improvement opportunities.