- Company

- Products

Petrochemicals

Refining

Sustainability

- Napcon AI

- Our Platform

- Hybrid Process Modelling

- Resources

FCC Ethylene/Propylene

Optimization Advisor

Optimizing FCC Efficiency with Smart Recommendations.

Physics Meets AI: Hybrid Models for Optimization.

Watch Demo

FCC Ethylene/Propylene Optimization Advisor

10%

Increase in Propylene Product Yield

12%

Increase in Overall Ethylene & Propylene Product Yield

Hybrid Model

Our model provides precise operator setpoints for optimizing key variables in two scenarios: Fixed Riser Operating Temperature and Variable Riser Operating Temperature. In both scenarios, ethylene and propylene yields are maximized by adjusting:

- Riser pressure

- Dispersion steam rate

- Coker naphtha recycle rate

- Dense bed temperature

Transform your Challenges into Opportunities

Pain Point

Yield Limitations at Maximum Riser Operating Temperature (ROT)

Benefit

Fixed ROT Maximization Optimizer: Provides insights into possible yield increases for both ethylene and propylene.

Pain Point

Uncertainty in Optimization Mode Selection

Benefit

Dual ROT Optimization: Evaluates both fixed and variable ROT scenarios to reveal potential yield improvements.

Performance Deviation Prediction

DCS and LIMS data for both feed and product streams are captured, providing essential input for analysis and optimization.

Key Parameter Monitoring

Operators select the optimization mode—Fixed ROT or Variable ROT—to maximize ethylene and propylene (E+P) yield

Process and Efficiency Trends

The optimizer runs hourly based on the last selected optimization mode and the latest DCS and LIMS data, ensuring up-to-date analysis.

Operational Benchmarking

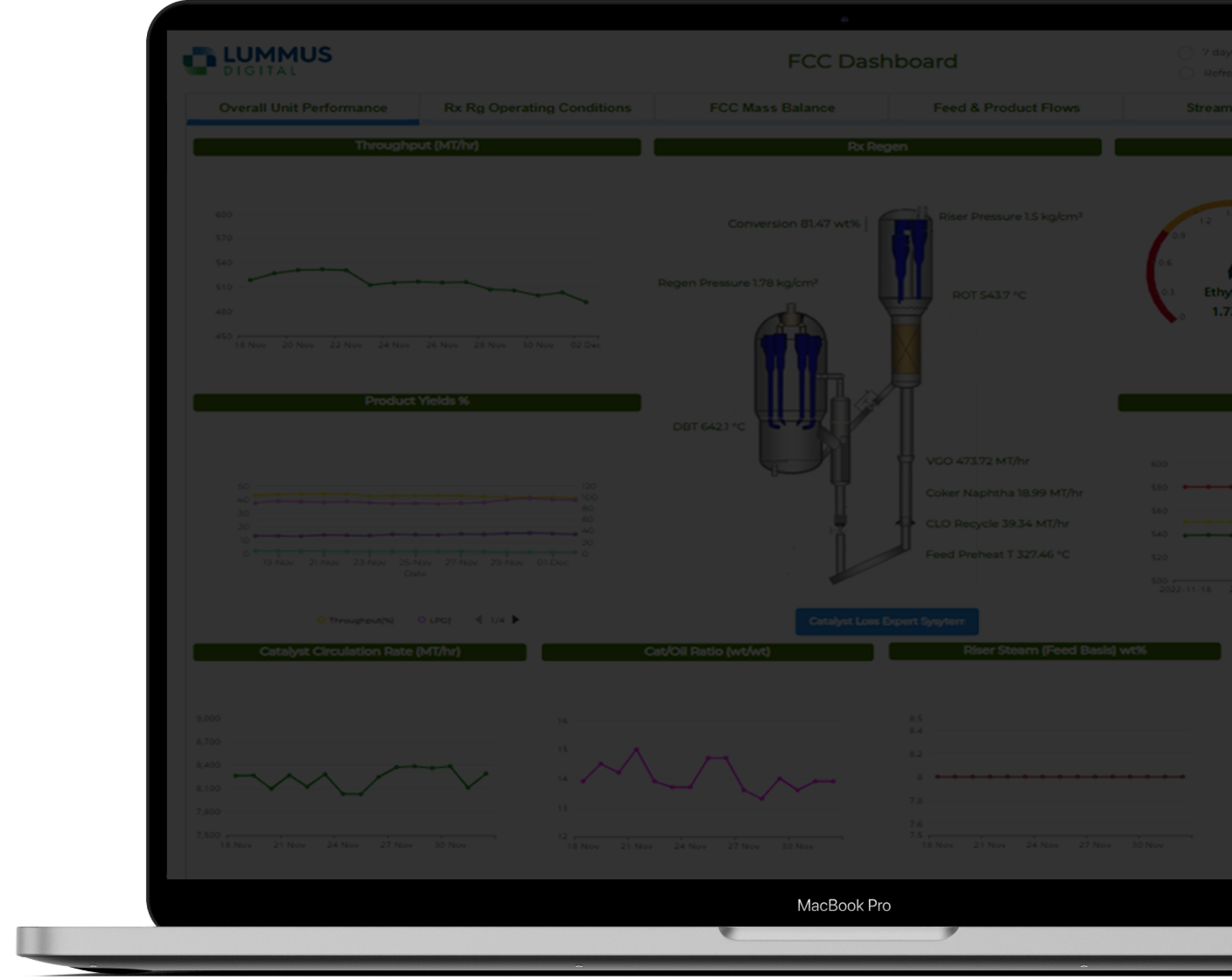

The Results from the optimizer are published on the Dashboard table.

Actionable Insights for Improvement

Comparison plot between “Current Operation” vs. “Optimized Operation“ is shown on the Dashboard.