Inventory Optimization for a Large…

Case Studies Business Objective: Drive efficiencies in the Supply Chain…

Business Objective:

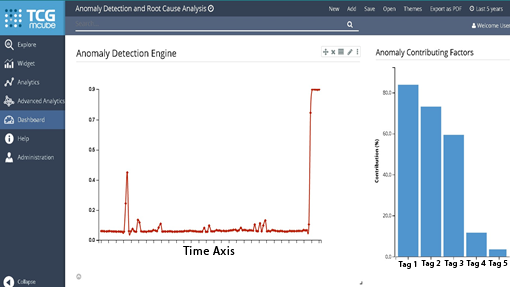

To implement Digital Transformation of a Petrochemical Plant in Africa to avoid Process Upsets/ Incidents and Production Loss.

A petrochemical plant in Africa needed to equip itself with necessary technology that would help avert process upsets/incidents and production losses. The business objective included:

Key Solution:

Due to an upset in upstream system or around the solvent stripper of petrochemical plant, the solvent ppm in outlet product stream increases. High solvent ppm in pellets along with high conveying air temperature can ignite pellets and cause fire in the downstream system.

Business Impacts & Outcomes:

Case Studies Business Objective: Drive efficiencies in the Supply Chain…

Case Studies Business Objective: To increase Uptime of an Offgas…

Case Studies Business Objective: Produce polymer grades at optimal levels…

*Sample Values for Representation Purpose