- Company

- Products

Petrochemicals

Refining

Sustainability

- Napcon AI

- Our Platform

- Hybrid Process Modelling

- Resources

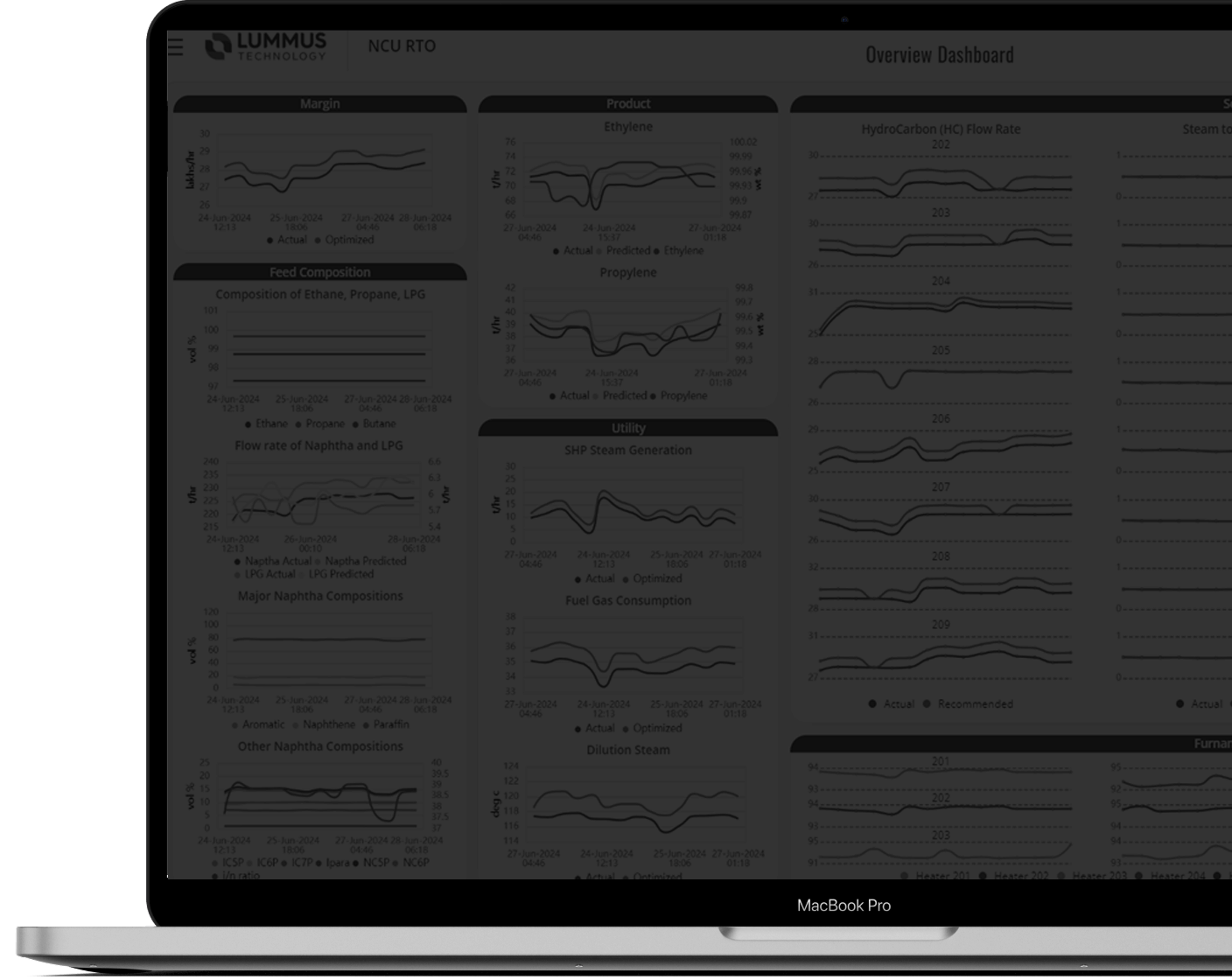

Naphtha Cracker Real-Time Optimization

Peak Performance. Product Consistency. Enhanced Profitability.

Physics Meets AI: Hybrid Models for Optimization.

Naphtha Cracker Real-Time Optimization Solution—an integrated First-Principles Simulation and AI/ML-powered platform that maximizes margin by tapping into your plant data system and predicting Product Quality in real time. Tailored for process engineers and plant operators, it helps you run your unit at peak performance, maintain premium product quality, and unlock significant cost savings across your operations.

Watch Demo

Ethylene Heater Optimizer

2%

4%

Hybrid Model

A hybrid model integrates a first-principles model (based on physical laws) with a machine learning model (data-driven predictions) to enhance accuracy and flexibility. The first-principles model provides a structured, mechanistic understanding of the system while machine learning fills in the gaps, manages uncertainties, and adapts to complex, real-world scenarios. By combining the two, the fundamental engineering laws in the first-principles model work together with data-driven algorithms in the prediction model to optimize compressor performance.

Persons name, Company name

The AI-driven predictions from Lummus Digital helped us fine-tune our processes and maintain consistent product quality.

By leveraging real-time insights, we’ve reduced downtime, improved efficiency, and achieved significant cost savings across our operations. This solution has empowered our team to make smarter, data-driven decisions, ensuring optimal performance and long-term reliability

Persons name, Company name

The AI-driven predictions from Lummus Digital helped us fine-tune our processes and maintain consistent product quality.

By leveraging real-time insights, we’ve reduced downtime, improved efficiency, and achieved significant cost savings across our operations. This solution has empowered our team to make smarter, data-driven decisions, ensuring optimal performance and long-term reliability

Persons name, Company name

The AI-driven predictions from Lummus Digital helped us fine-tune our processes and maintain consistent product quality.

By leveraging real-time insights, we’ve reduced downtime, improved efficiency, and achieved significant cost savings across our operations. This solution has empowered our team to make smarter, data-driven decisions, ensuring optimal performance and long-term reliability

Your Digital Transformation Roadmap Starts Here

Discover key strategies and actionable insights to fast-track your digital transformation journey and drive meaningful results.

Transform your Challenges into Opportunities

By adopting a Real-Time Optimization (RTO) solution for ethylene heaters, you can turn challenges into strategic opportunities. With the right tools, your operations can achieve greater efficiency, reduced costs, and improved sustainability—all while maximizing profitability.

Pain Point

Struggling to boost throughput and profitability

Benefit

Optimize throughput and profit with precise Heater COT and Steam-to-Oil Ratio adjustments

Pain Point

Uncertainty in determining the ideal Heater COT setpoint

Benefit

Get accurate Heater COT set points tailored to your feed using optimizer insights and PYPS+ analysis

Pain Point

Unclear achievable yield for specific feed compositions

Benefit

Unlock insights with the Scenario Analysis feature, which provides the potential yield based on Naphtha feed composition

Performance Deviation Prediction

The PYPS+ Model takes the Plant Feed Composition, Feed rate, and the current DCS operating data as input

Key Parameter Monitoring

Process and Efficiency Trends

Based on the optimizer mode selection and the Scenario Analysis run (PYPS+), the RTO provides setpoints for the operator to achieve the desired results.

Operational Benchmarking

The model re-runs a scenario analysis after the optimizer run is complete to analyze actual results in PYPS+ once the changes are implemented.

Actionable Insights for Improvement

Margins are calculated for before RTO, with RTO, and after RTO to assess profit impact, and the results are published in a report.