- Company

- Products

Petrochemicals

Refining

Sustainability

- Napcon AI

- Our Platform

- Hybrid Process Modelling

- Resources

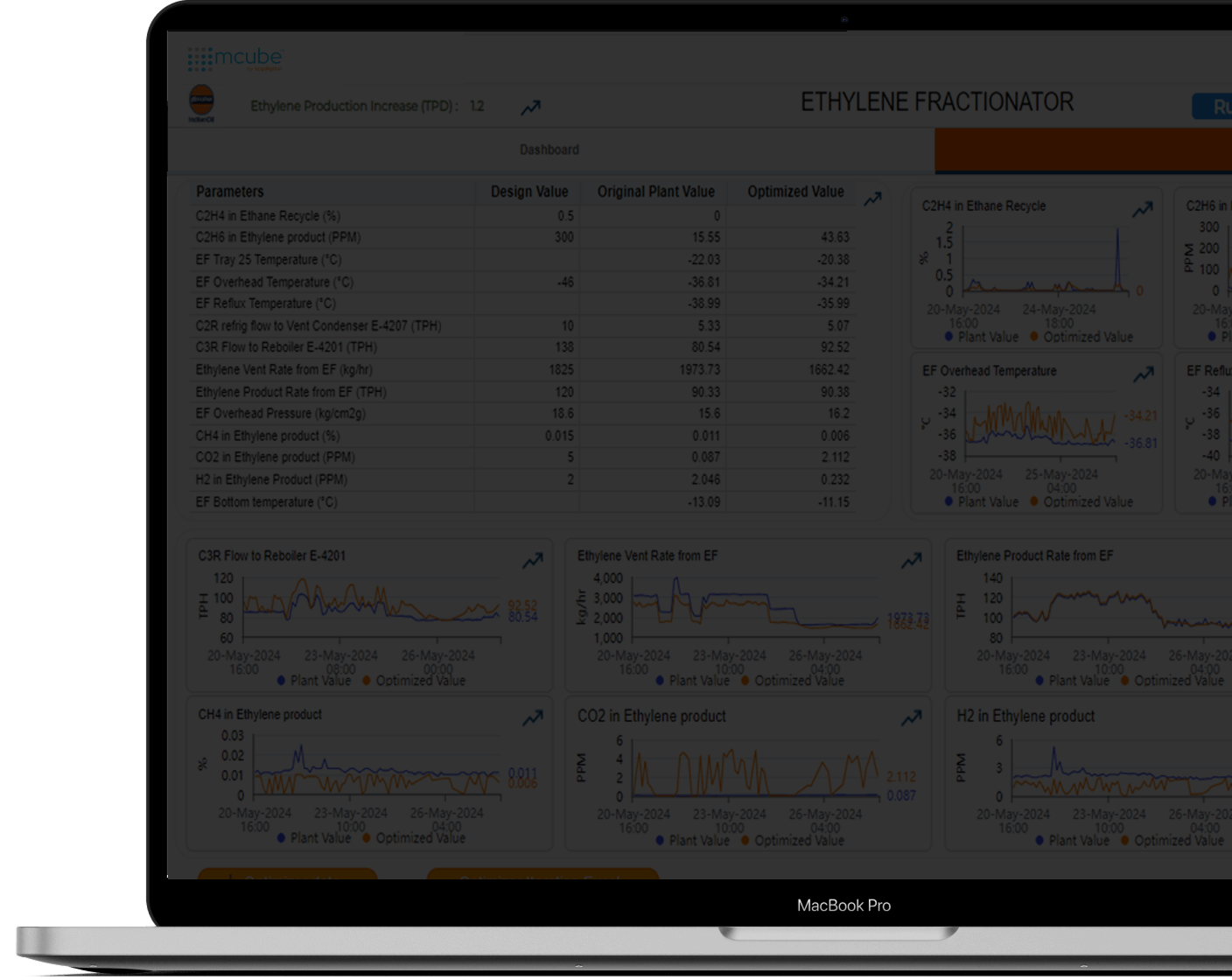

Ethylene Fractionator Optimization

Enhance Ethylene Production with AI-Driven Optimization.

Introducing the Ethylene Fractionator Column Optimization Solution — an AI/ML-powered platform designed to maximize ethylene product yield while minimizing ethylene slippage in the bottom ethane recycle stream. By leveraging real-time DCS data, it optimizes utility consumption and reduces ethylene vent rates. Tailored for process engineers and plant operators, this solution ensures your column runs at peak efficiency—helping you achieve higher ethylene yield, reduce losses, and unlock significant cost savings across your operations.

Watch Demo

Ethylene Fractionator Optimizer

3%

Increase in Overall Ethylene Recovery

3%

Reduction in Refrigerant Consumption

Hybrid Model

Our model utilizes real-time ethane content data in ethylene and, based on the required on-spec ethylene product specifications, delivers precise operator setpoints for optimizing key variables. These include:

- Column top pressure

- Reboiling stream flow rate

- Vent rate

With these optimizations, the model increases ethylene product draw rates from the distillation column, ensuring consistent on-spec production while improving overall column efficiency and operational performance.

Transform your Challenges into Opportunities

Pain Point

Ethylene Product Loss & Heater Maintenance Issues

Benefit

Reduced Ethylene Slippage: Optimized reboiling and condensing operations push ethylene quality to spec limits, minimizing product loss

Pain Point

Increased Operational Cost due to higher Vent and Recycle rates

Benefit

Lower Vent & Recycle Rates: Reduced ethylene venting and ethane recycle with minimal slippage

Pain Point

Reduced Ethylene Recovery (Product-to-Feed Ratio)

Benefit

Maximized Ethylene Recovery: Optimized column operations leverage design specification margins to enhance ethylene product yield

Pain Point

High Refrigerant Consumption

Benefit

Optimized Refrigerant Use: Decreased refrigerant consumption and improved recovery through increased reboiling

Performance Deviation Prediction

Takes the DCS and LIMS data with respect to the Ethylene Fractionator for further analysis and processing.

Key Parameter Monitoring

Process and Efficiency Trends

The alert indicates if the unit is operating normally (displays “Ethylene Product is on-spec”) or not, and provides recommended operator actions and upcoming event forecasts.

Operational Benchmarking

The model runs and publishes recommended values for operator-controlled setpoints to achieve lower vent rates, minimize ethylene slip, and maximize on-spec ethylene product rates.

Actionable Insights for Improvement

Displays a comparison plot of Current Operation vs. Optimized Operation on the dashboard to highlight potential areas for improvement.