- Company

- Products

Petrochemicals

Refining

Sustainability

- Napcon AI

- Our Platform

- Hybrid Process Modelling

- Resources

Digital Decarb – GHG Emission

Monitoring and Analysis Tool

Unlock Carbon Efficiency with Real-Time GHG Monitoring.

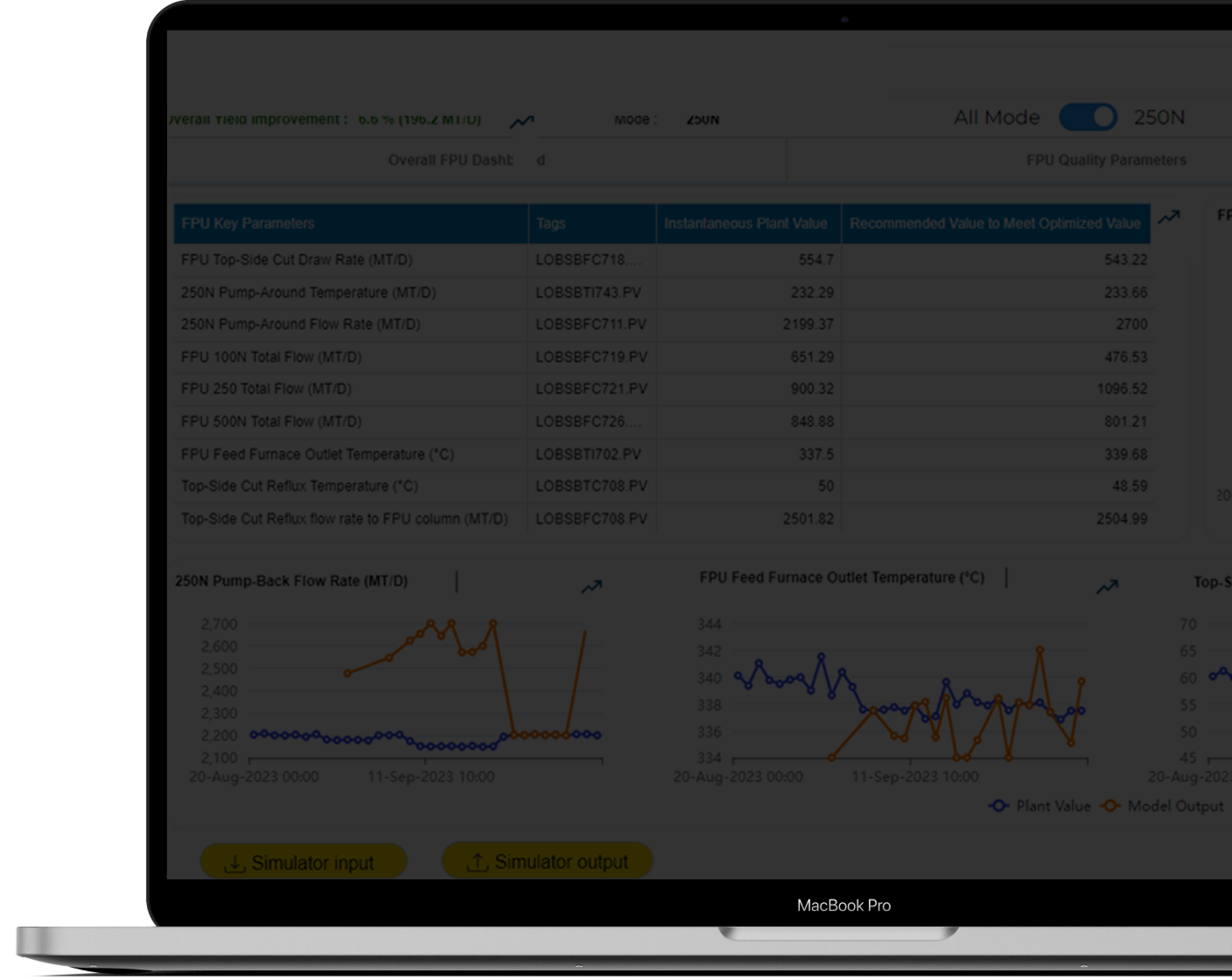

Physics Meets AI: Hybrid Models for Optimization

Introducing Digital Decarb, a cutting-edge solution designed to estimate, monitor, and analyze GHG emissions (Scope 1 and 2) in real time. By leveraging data on fuel types, compositions, emission sources, and other key factors, our advanced AI/ML-driven platform empowers you to perform dynamic “what-if” analyses.

This enables the exploration of alternative scenarios, assessing emissions based on varying fuel sources or configurations, and driving more informed, sustainable decision-making.

Watch Demo

Digital Decarb

Allows 5-10%

efficiency improvement opportunities

Faster response and identification of potential sources of emissions

Transform your Challenges into Opportunities

CGC Efficiency Monitoring is designed to address the critical challenges faced by industrial operations, providing advanced AI-driven solutions that not only predict and prevent potential issues but also optimize performance, reduce costs, and enhance overall efficiency

Pain Point

Inability to Estimate GHG Emission from the Unit

Benefit

Real-time estimation and monitoring of Scope 1 and Scope 2 GHG emissions.Pain Point

Difficulty in managing multiple emission sources and minimizing net emissions

Benefit

Track and manage emissions across multiple levels—from individual assets to units and up to complex multi-unit configurations.

Pain Point

High energy consumption and operational inefficiency

Analyze energy consumption and identify potential emission sources. Perform what-if analyses for alternative fuel sources or system configurations to identify the most effective decarbonization route.

Pain Point

Automated reporting system for audit purposes

Benefit

Customizable, automated reporting system for daily, monthly, or annual energy and emission data—ready for audits and regulatory submissions.

Performance Deviation Prediction

Predicts the rate of fouling in each compression stage, including associated intercoolers/ heat exchangers.

Key Parameter Monitoring

Stage-wise compressor monitoring of: Pressure rise, Temperature rise, After cooler differential pressure (ΔP), and After cooler differential temperature (ΔT)

Process and Efficiency Trends

Trend plots for:

- Wash Oil Injection

- Attemperation Water

- Antifoulant Injection

- Polytropic Efficiency (%)

- Theoretical vs. Actual Compressor Efficiency

Operational Benchmarking

Actionable Insights for Improvement