- Company

- Products

Petrochemicals

Refining

Sustainability

- Napcon AI

- Our Platform

- Hybrid Process Modelling

- Resources

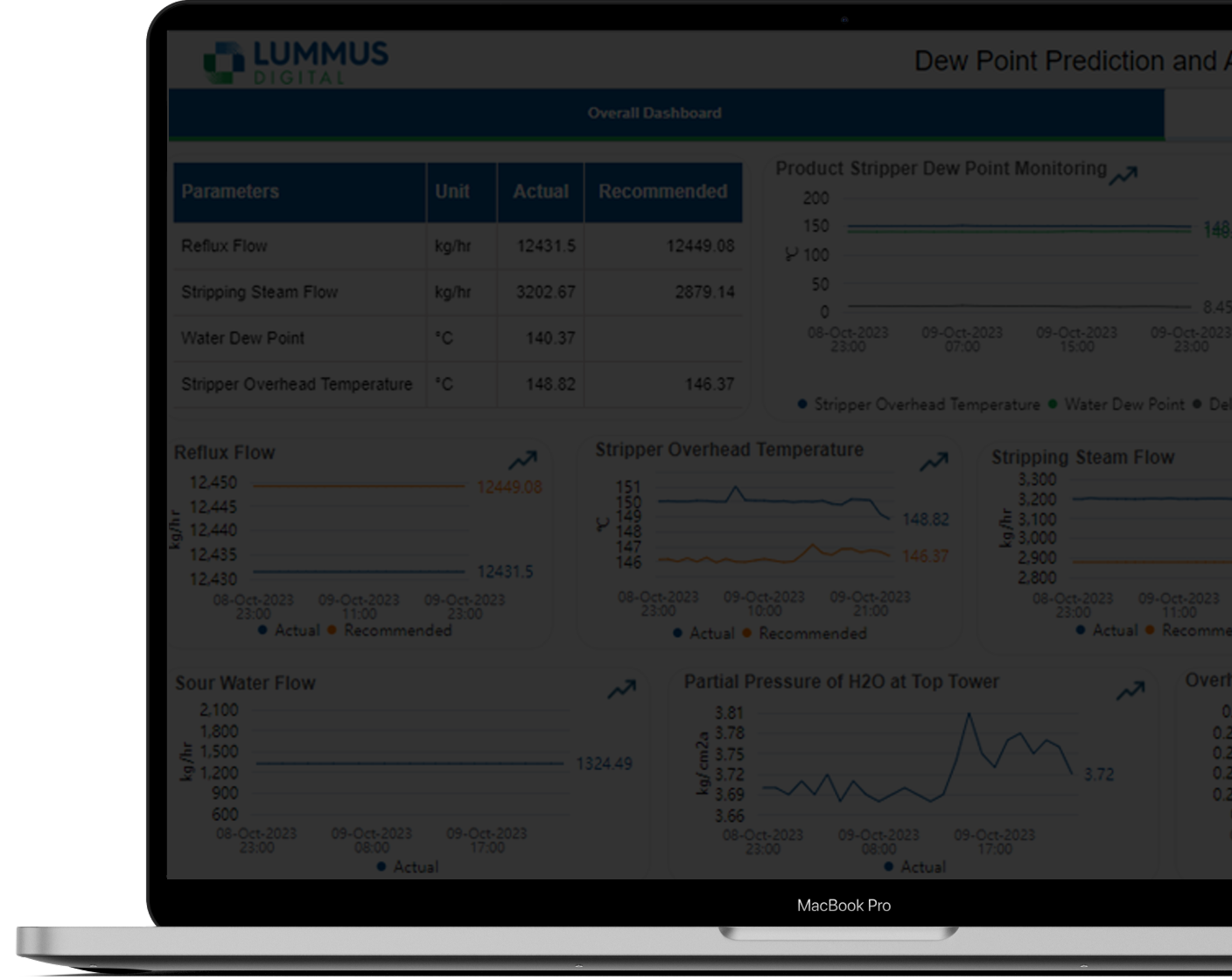

Dew Point Monitoring

and Advisor

Optimize Refinery Performance. Enhance Quality. Minimize Environmental Risks.

Product Introduction:

Product Stripper dew point issues in refineries can create significant operational hurdles, including off-spec products, hydrocarbon condensation, and decreased throughput. These challenges lead to inefficiencies in separation processes, adversely affecting product quality and escalating reprocessing costs.

To mitigate these issues, operators often increase reboiler heat, resulting in higher energy consumption and diminished plant efficiency.

Additionally, dew point mismanagement can lead to equipment fouling, corrosion, and potential damage to downstream compressors from liquid carryover. This not only drives up maintenance costs and unplanned downtime but also introduces environmental and safety risks associated with venting or flaring.

By addressing dew point management effectively, refineries can enhance performance, reduce costs, and maximize profitability.

Watch Demo

Dew Point Prediction and Advisor

20%

Reduction in Maintenance Costs

30%

Reduction in Unscheduled Unit Shutdowns

25%

Increase in Equipment Lifespan

Hybrid Model

A hybrid model combines first-principles approaches with machine learning techniques to optimize dew point management in hydroprocessing strippers. The first-principles component employs physical laws to accurately determine dew point conditions and understand the operational dynamics of steam condensation.

Meanwhile, the machine learning model leverages historical data and real-time inputs to adaptively predict optimal reflux and stripping steam flow values.

This synergy allows for improved accuracy in forecasting system behavior, effectively managing uncertainties and complex operational scenarios. By integrating these methodologies, the hybrid model enhances the reliability of dew point predictions, ensuring optimal conditions for maintaining “On-spec” product quality.

Transform your Challenges into Opportunities

Pain Point

Steam Condensation Risks and Fouling Problems

Benefit

Real-time monitoring and adjustments enable operators to maintain optimal operating conditions, enhancing process stability, boosting productivity by 10%, and delivering an annual revenue increase of $100,000 alongside total savings of approximately $250,000.

Pain Point

Limited Operational Flexibility and Reduced Product Quality

Benefit

Real-time monitoring and adjustments enable operators to maintain optimal operating conditions, enhancing process stability, boosting productivity by 10%, and delivering an annual revenue increase of $100,000 alongside total savings of approximately $250,000.

Pain Point

Unplanned Shutdowns and Increased Maintenance Frequency

Benefit

Optimize energy usage and enhance the equipment lifespan with actionable recommendations based on AI-driven insights and hybrid model approaches.

Pain Point

Lack of Proactive Management

Benefit

Predictive insights inform maintenance schedules, enabling proactive measures to address potential issues and extend equipment life by 20%, saving a medium-sized industrial plant approximately $150,000 annually based on a $750,000 replacement cost every five years.

Performance Deviation Prediction

Calculate the dew point with precision and suggest the most optimal top temperature settings to prevent steam condensation from occurring during the process.

Key Parameter Monitoring

Complete monitoring of all parameters, including Naphtha flow, off-gas flow, reflux flow, steam flow, top pressure, and top temperature.

Process and Efficiency Trends

Trend plots for

- Dew point

- Overhead temperature

- Top pressure & Partial pressure

- Reflux flow, Off-gas flow, and Naphtha flow

Operational Benchmarking

Comparison plot and table between “Actual” vs. “Recommended “ for

1. Overhead Temperature

2.Reflux Flow

3.Stripping Steam Flow

Actionable Insights for Improvement

Actionable recommendations (based on comparison with current values) on controllable parameters such as reflux flow and stripping steam flow.