- Company

- Products

Petrochemicals

Refining

Sustainability

- Napcon AI

- Our Platform

- Hybrid Process Modelling

- Resources

Physics Meets AI: Hybrid Models for Optimization.

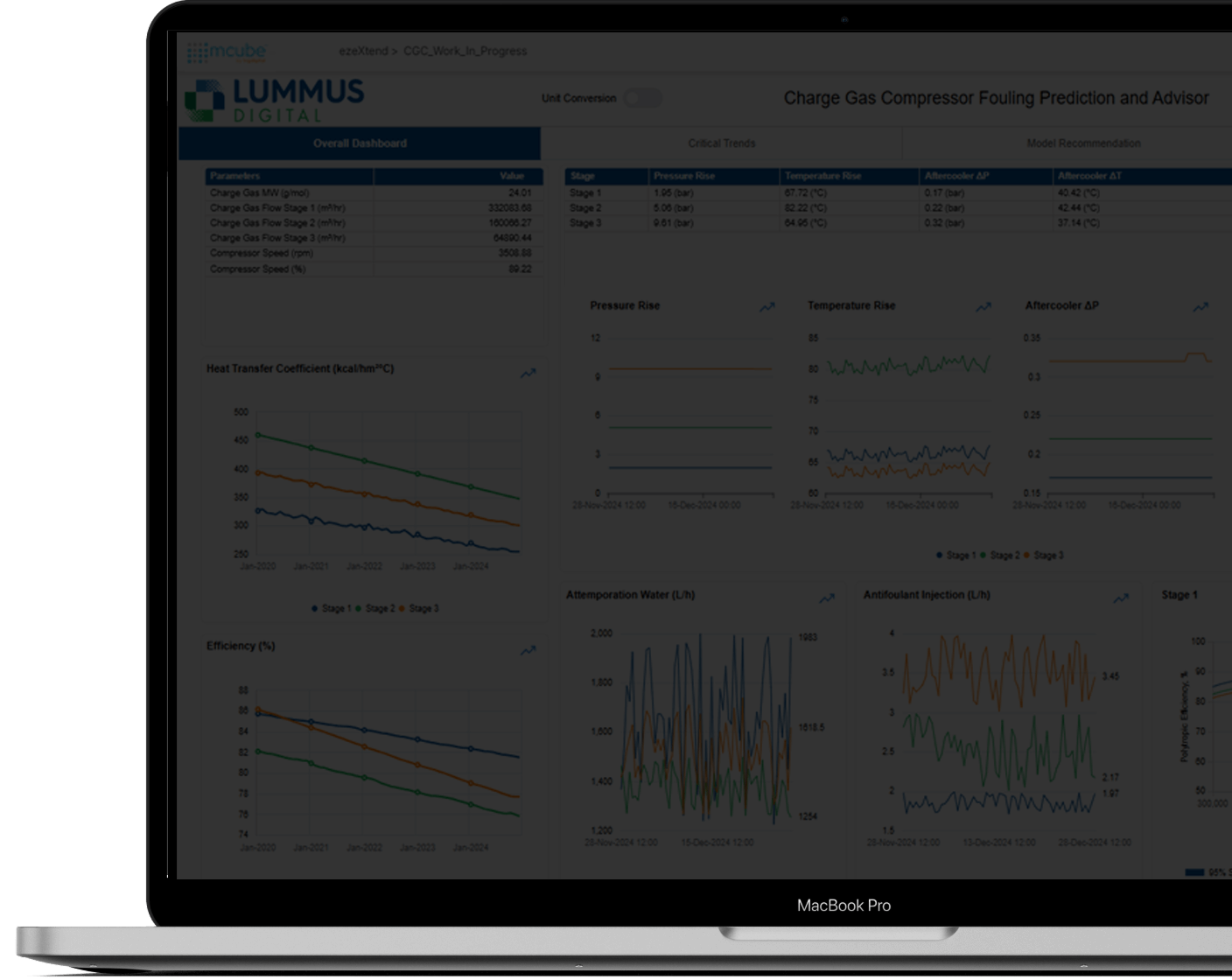

Introducing the CGC Efficiency Monitoring solution, designed to optimize the operational performance of Charge Gas Compressors (CGC) by predicting and mitigating fouling issues in real-time. Our advanced hybrid model empowers process engineers to maintain optimal efficiency, reduce downtime, and drive cost savings across your operations.

Watch Demo

CGC Fouling Mitigator

10%

Increase in Compressor Lifespan

50%

Faster Response to Potential Anomalies

Hybrid Model

A hybrid model integrates a first-principles model (based on physical laws) with a machine learning model (data-driven predictions) to enhance accuracy and flexibility. The first-principles model provides a structured, mechanistic understanding of the system, while machine learning fills in the gaps, manages uncertainties, and adapts to complex, real-world scenarios. By combining these, the fundamental engineering laws in the first-principles model work together with data-driven algorithms in the prediction model to optimize compressor performance.

Transform your Challenges into Opportunities

Pain Point

Inability to Predict Fouling Issues in Real-time

Benefit

Real-time monitoring and predictive analytics identify potential fouling issues before they cause operational disruptions.

Pain Point

Difficulty in Managing Multiple Compressor Stages Simultaneously

Benefit

Monitor and manage up to six compressor stages, along with aftercoolers, through a comprehensive and flexible dashboard designed to meet your specific needs.

Pain Point

High Energy Consumption and Operational Inefficiency

Benefit

Optimize energy usage and enhance efficiency with actionable recommendations based on AI-driven insights and hybrid model approaches.

Pain Point

Unplanned Downtime and Increased Operating Costs

Benefit

Minimize unplanned downtime with predictive maintenance capabilities, reducing both costs and operational risks.

Performance Deviation Prediction

Predict the fouling rate at each compression stage along with the corresponding fouling rates for related intercoolers and heat exchangers, based on real-time operational data and conditions.

Key Parameter Monitoring

Stage-wise monitoring of compressor parameters, including pressure rise, temperature rise, after-cooler differential pressure (ΔP), and after-cooler differential temperature (ΔT)

Process and Efficiency Trends

Operational Benchmarking

A comparison plot between “Current Operation” and “Recommended Operation” is displayed, allowing for a clear visual assessment of the two operational scenarios.

Actionable Insights for Improvement

Actionable recommendation (comparing with current values) on controllable parameters (each stage- wise) like Wash Water Injection, BFW Injection, Antifoulant Injection, and Fouling Rate.