- Company

- Products

Petrochemicals

Refining

Sustainability

- Napcon AI

- Our Platform

- Hybrid Process Modelling

- Resources

Physics Meets AI: Hybrid Models for Optimization.

Watch Demo

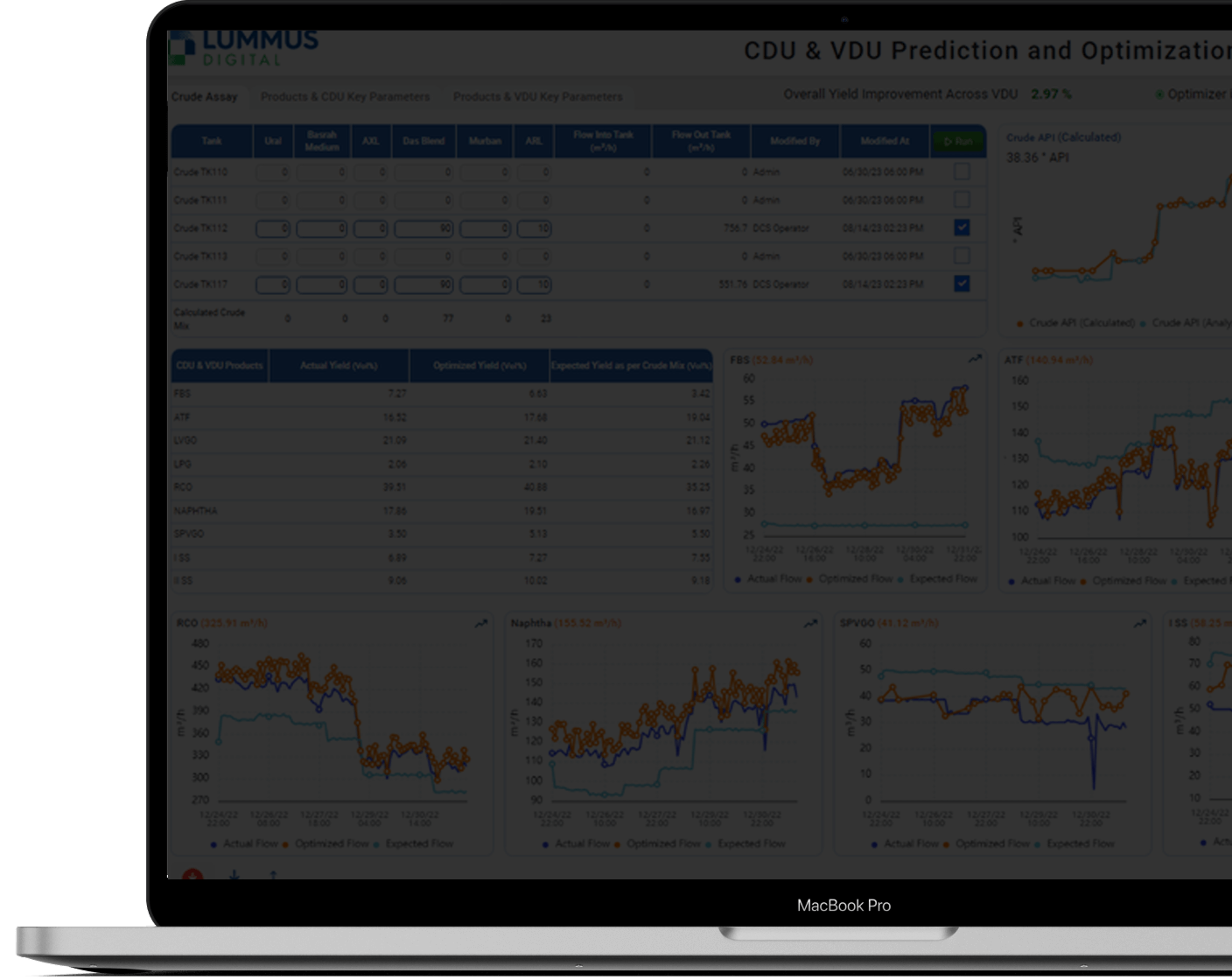

CDU & VDU Predictor and Optimizer

10%

VTB shifted into higher-value middle streams, driving significant profit gains.

98%

Precision in predicting viscosity, flash point, and VTB pen, ensuring consistent product quality.

Hybrid Model

- Stripping steam flow rate

- Pump around flow rates and temperatures

- Reflux flows

- Draw rates with information on draw temperatures

Additionally, it provides optimized values for viscosity, flash point, and VTB pen test, ensuring consistent on-specification product quality while improving overall column efficiency and performance.

Transform your Challenges into Opportunities

Pain Point

Crude Blend Uncertainty

Benefit

Crude Mix Clarity: Our crude mix model accurately determines the processed blend by integrating analyzer API values with user-provided crude mix data.

Pain Point

Unstable Operation During Crude Changeovers

Benefit

Dynamic Crude Optimization: The model adapts to varying crude blends, providing optimized set points for each combination, ensuring smooth operations and stability.

Pain Point

Loss of High-Value Streams

Benefit

Maximized Product Value: The model optimizes VTB blending with higher-value middle streams, keeping all quality parameters within spec limits to maximize profitability.

Pain Point

Low Frequency Sampling of Side-Streams and Vacuum Tower Bottom

Benefit

Real-Time Quality Predictions: Our model delivers high-frequency, real-time predictions of key quality metrics, enabling faster, more accurate control.

Performance Metrics

Powerful, self-serve product and growth analytics to help you convert, engage, and retain more users. Trusted by over 4,000 startups.

Performance Deviation Prediction

Operator enters the estimated crude mix on the dashboard and initiates the run.

Key Parameter Monitoring

The Crude Mix Model calculates the accurate crude mix and displays the results on the dashboard.

Process and Efficiency Trends

Every two hours, the prediction model runs to predict the Viscosity, Flash Point, and VTB Penetration Test values at operating conditions.

Operational Benchmarking

Using the corrected crude mix and predicted product quality parameters, the Optimizer Model runs and populates a table of actual and optimized/recommended values.

Actionable Insights for Improvement

A comparison plot between “Current Operation” and “Optimized Operation” is displayed on the dashboard for operator action.