- Company

- Products

Petrochemicals

Refining

Sustainability

- Our Platform

- Hybrid Process Modelling

- Resources

Product Introduction:

Elevate your production with the LOBS Optimization Advisor—an advanced AI/ML-powered platform engineered to maximize a particular grade cut yields from the FPU and significantly boost lube oil output from the LOBS unit. Designed specifically for process engineers and plant operators, this solution ensures optimal performance by maintaining viscosity, viscosity index, Noack and CCS within precise specification limits. Unlock peak efficiency, enhance side stream yields, reduce losses, and achieve substantial cost savings across your operations with this powerful, tailor-made optimization tool.

Watch Demo

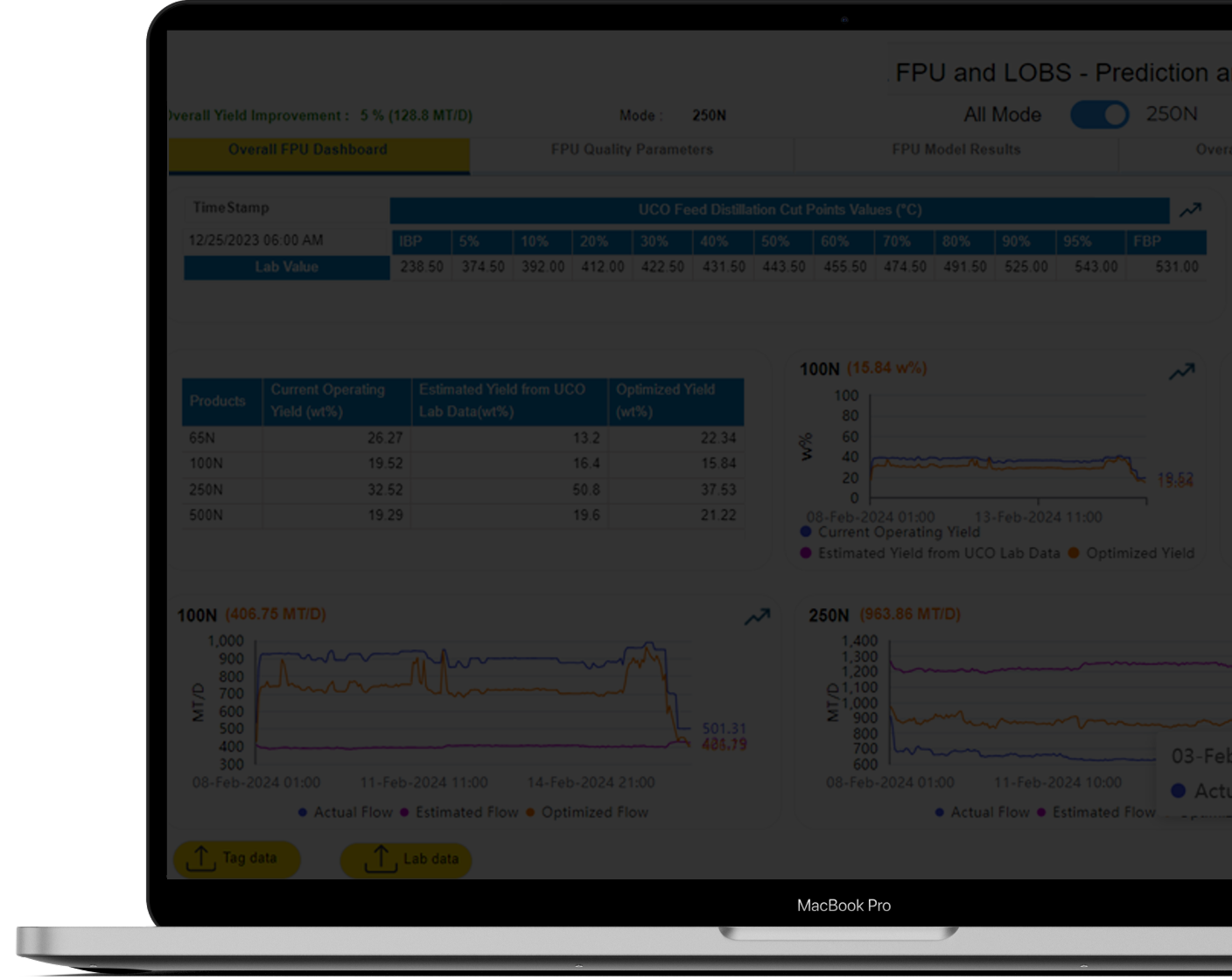

FPU and LOBS – Prediction and Optimization

5%

Increase in 250N Lube oil Product yield in LOBS.

98%

Accuracy in prediction of Viscosity for all streams

Hybrid Model

Our model empowers operators with precise set points to optimize critical variables in both the FPU and LOBS sections, driving maximum 250N cut yields. By fine-tuning essential parameters, the model enables increased efficiency and yield in each stage

FPU

- Adjust Heater COT

- Optimize Column Reflux Rate

- Manage Pump Around Flows

- Set the Draw rates for 65N, 100N, 250N and 500N streams from the Vacuum Tower

LOBS

- Controlling Stripper Top Temperature

- Optimize IDW and HDF Reactor CAT

- Set HP/LP Separator Pressure for peak performance

Persons name, Company name

The AI-driven predictions from Lummus Digital helped us fine-tune our processes and maintain consistent product quality.

By leveraging real-time insights, we’ve reduced downtime, improved efficiency, and achieved significant cost savings across our operations. This solution has empowered our team to make smarter, data-driven decisions, ensuring optimal performance and long-term reliability

Persons name, Company name

The AI-driven predictions from Lummus Digital helped us fine-tune our processes and maintain consistent product quality.

By leveraging real-time insights, we’ve reduced downtime, improved efficiency, and achieved significant cost savings across our operations. This solution has empowered our team to make smarter, data-driven decisions, ensuring optimal performance and long-term reliability

Persons name, Company name

The AI-driven predictions from Lummus Digital helped us fine-tune our processes and maintain consistent product quality.

By leveraging real-time insights, we’ve reduced downtime, improved efficiency, and achieved significant cost savings across our operations. This solution has empowered our team to make smarter, data-driven decisions, ensuring optimal performance and long-term reliability

Your Roadmap to Digital Transformation Awaits You Today.

Discover key strategies and actionable insights to fast-track your digital transformation journey and drive meaningful results.

Transform your Challenges into Opportunities

CGC Efficiency Monitoring is designed to address the critical challenges faced by industrial operations, providing advanced AI-driven solutions that not only predict and prevent potential issues but also optimize performance, reduce costs, and enhance overall efficiency

Experience increased conversion, real-time predictions of downstream Feed and product quality parameter values, and optimized hydrogen consumption, transforming your operations for enhanced efficiency and profitability!

Pain Point

Loss of 250N Yield Potential

Benefit

Enhanced 250N Cut: The model maximizes 250N yield in FPU and boosts 250N lube oil output in LOBS, ensuring maximum product recovery and profitability.

Pain Point

Delayed Detection of Side Stream Quality Variations

Benefit

High-Frequency Quality Tracking: Real-time sampling of viscosity and pour point in side streams enables precise quality control and rapid adjustments, maintaining optimal output specifications.

Performance Deviation Prediction

The operator enters the UCO Feed Quality (Distillation Sample) data on the dashboard for analysis of the feed quality parameters.

Key Parameter Monitoring

Process and Efficiency Trends

Every hour, the prediction model runs to predict the Viscosity of all side streams, and the formula calculates the Viscosity Index

Operational Benchmarking

Actionable Insights for Improvement

Comparison plot between “Current Operation” vs. “Optimized Operation“ is shown on the Dashboard